Project Description

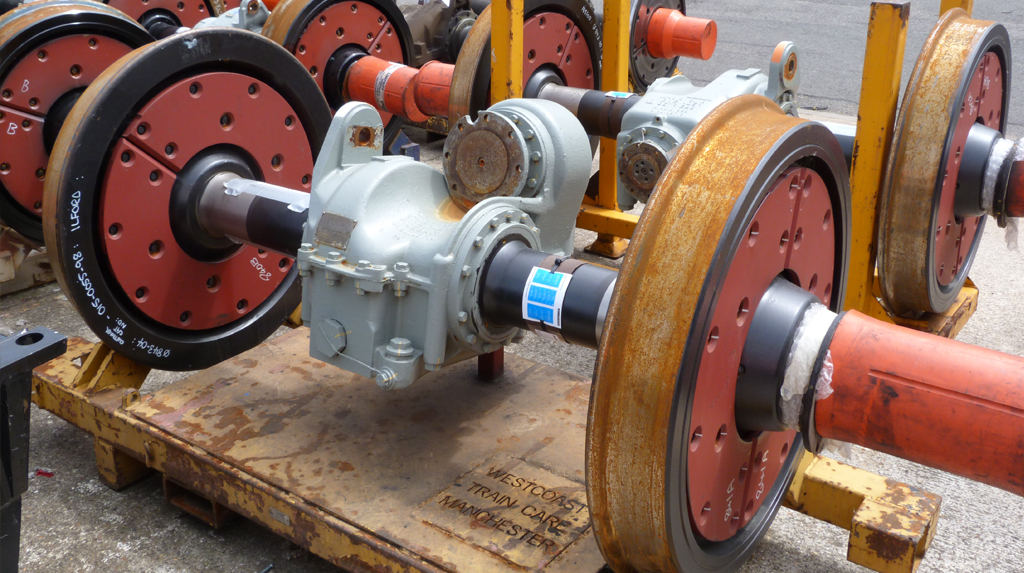

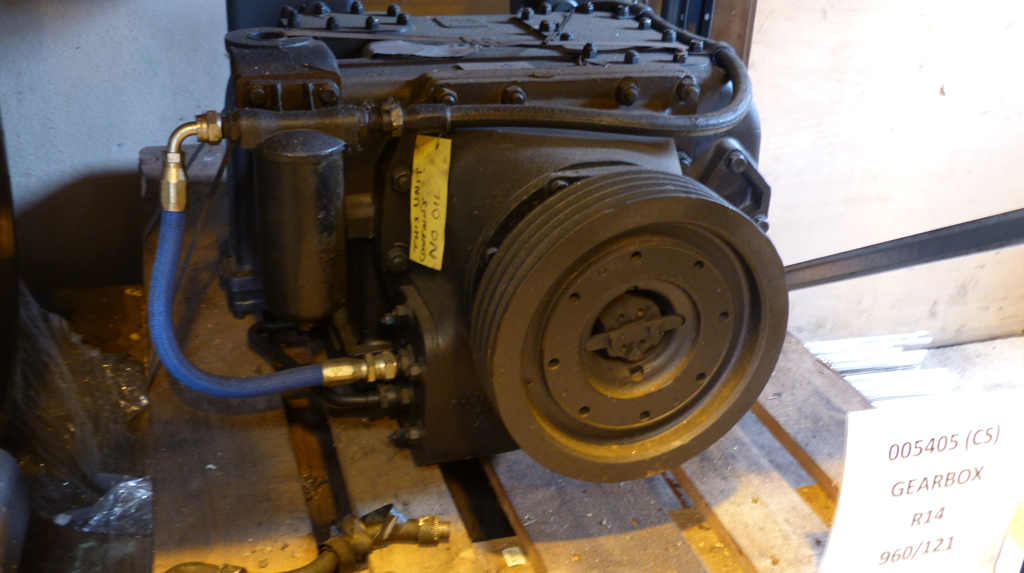

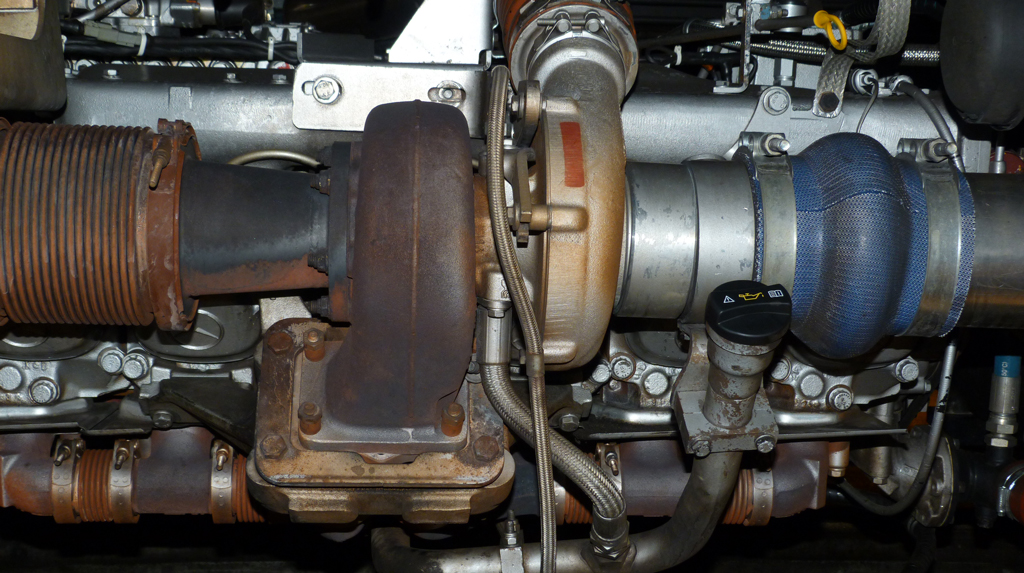

Routine train inspection and maintenance is a continuous activity ensuring equipment is maintained to an acceptable safety standard. Preventing failure of expensive major components (engines, gearboxes, wheel sets, axle bearings) and safely maximising their service life is the key to an efficient railway. Many components are best monitored in near service conditions with the train moving & fresh from service, rather than stationary in the depot and cooled down.

This cannot be done by humans so a robotics solution is ideal.

GOBOTiX has developed VUES, a continuous automatic inspection system using computer vision. Specialist cameras and lighting are used to detect anomalies such as overheating components, damaged equipment and leaks of certain fluids. The train will pass over VUES several times each day without an interruption to its normal service routine and VUES will report any anomalies detected which can be further examined by a skilled engineer if required. Anomalies can be categorised by urgency so that appropriate action is taken.